The future development trend of palletizing robot

The future of palletizing robots will present four core trends: intelligence, collaboration, greening, and scenario-based. The deep integration of technological breakthroughs and industry needs will drive their evolution from “robotic arms” to “intelligent production brains”.

1. Technological evolution: from execution tools to intelligent decision-making centers

AI deep empowerment drives palletizing robots to upgrade from preset programs to autonomous decision-making. Robots equipped with AI algorithms can identify the size, weight, and material of goods in real time, and even detect internal states through thermal imaging to achieve dynamic stacking optimization of special-shaped goods.

The predictive maintenance system based on edge computing + digital twins can detect data such as joint wear and motor load with microsecond accuracy. Group intelligence realizes multi-robot collaborative operation through 5G + cloud scheduling.

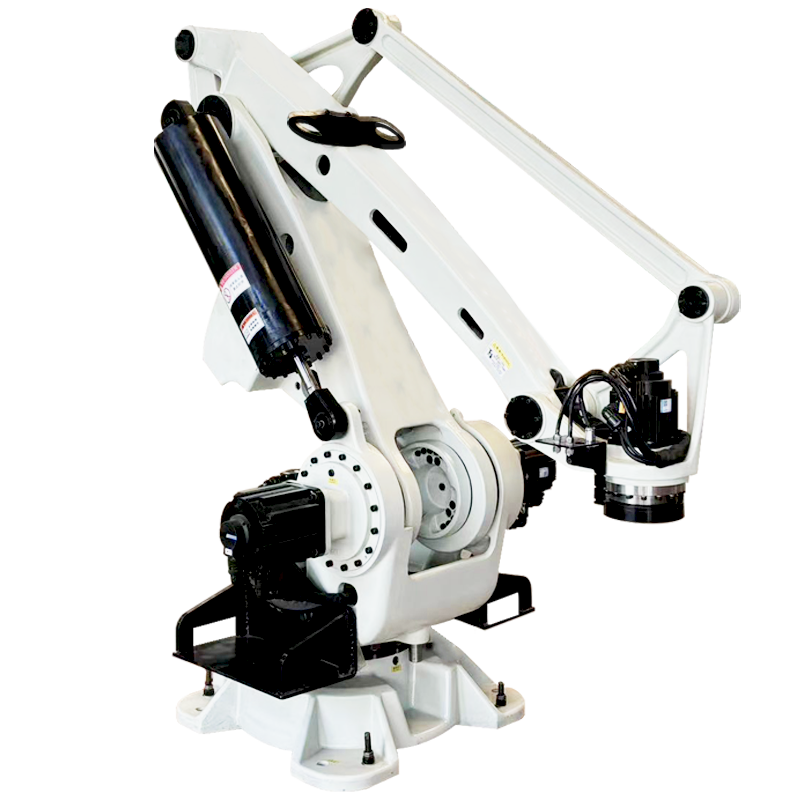

Hardware innovation focuses on lightweight and extreme environment adaptation. The robotic arm made of carbon fiber reinforced composite materials reduces the overall weight.

2. Industry transformation: from standardized production to flexible customization

The upgrade of the manufacturing industry drives the transformation of palletizing robots to “self-evolving production lines”. Mixed code scene breakthroughs have become the key, and process integration has accelerated penetration. The SP180 palletizing robot of Xinshida has integrated laser welding + handling functions to realize the full process automation of “welding – detection – palletizing” in the production of lithium battery modules.

3. Ecological reconstruction: from stand-alone equipment to industrial ecology

Software-defined hardware has become a trend. The low-code development platform realizes rapid programming through a graphical interface. Users can drag and drop to configure the pallet type without professional code knowledge. Digital twin technology builds a digital model of the robot through the Tencent Cloud platform to simulate the motion trajectory under different working conditions and shorten the debugging time.

4. Challenges and future prospects

Despite the broad prospects, palletizing robots still face cost bottlenecks, technical barriers and ethical disputes. In the next ten years, technological breakthroughs such as brain-computer interface control of high-risk environment operations, quantum computing to optimize storage space utilization, and biomimetic material flexible cargo palletizing will reshape the industry landscape.

The evolution of palletizing robots is essentially a process of “data-driven + physical world reconstruction”. It is not only a production tool, but also the core node of the enterprise’s digital transformation, driving the manufacturing industry towards the ultimate goal of “zero carbon, zero labor, and zero error”.uat. Duis aute irure dolored perspiciatis unde omnis iste natus error sit voluptatem accusantium.

Related recommendations

-

How depalletizing robot save labor

25The depalletizing robot realizes efficient and accurate material disassembly operations by integrating pneumatic technology and robotic systems.

View details -

Characteristics of industrial palletizing robot

20Palletizing robot have developed rapidly in many fields with their own advantages, and they are often seen in many industries such as manufacturing.

View details -

Automatic Wrapping Machine: Technological Innovation and Development in Tandem

31Automatic wrapping machine are achieving the leap from "mechanical operation" to "intelligent empowerment" through continuous technological innovation.

View details -

What industries can industrial palletizing robot be used in?

24Industrial palletizing robot have become the core equipment for intelligent upgrades in many industries with their efficient and preciseoperation capabilities

View details

Benson robots

Benson robots

HelloPlease log in