Automatic Wrapping Machine: Technological Innovation and Development in Tandem

122Automatic wrapping machine are achieving the leap from "mechanical operation" to "intelligent empowerment" through continuous technological innovation.

View detailsSearch the whole station

Key attributes

| packaging material | plastic, Paper, OPP/CPP/PE | packaging type | Cartons, CANS, Stand-up Pouch, Bags, Foil, Pouch |

| application | Food, Beverage, Commodity, Chemical, Machinery | driven type | Electric or Pneumatic |

| Filling Material | Powder, PASTE, Granule, Solid | warranty | 1 Year |

| Voltage | 220V 380V 50/60Hz 3Phase | function | FILLING, Wrapping, Labeling, Laminating, Capping |

| automatic grade | Automatic | after-sales service provided | Video technical support, Field installation, commissioning |

| Weight (KG) | 2000 | place of origin | Shandong, China |

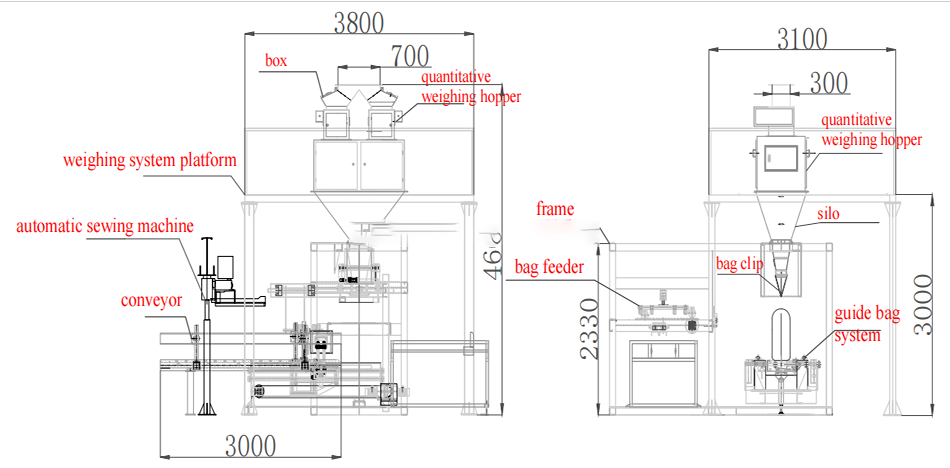

| brand name | BENSON | dimension(l*w*h) | 3100*2400*3800mm |

| key selling points | Easy to Operate | machinery test report | Provided |

| video outgoing-inspection | Provided | core components | motor, Pressure vessel, Pump, PLC, Engine, Gearbox, Other |

| Product name | Fully Automatic Packing Machine | Main function | packaging |

| Packaging speed | 450-600bags/h | Sealing type | sewing |

| Marketing Type | Ordinary Product | Application | Medical |

Product descriptions from the supplier

Video Description

MACHINE SHOW

What open-mouth baggers can do and handle?Our bagging machines can pack a variety of dry products into 25lb, 50lb, and 100lb bags.

Various bulk materials

* Granules and pellets like pet food, animal feed, rice, cereal grains, and fertilizers.

* Powders like flour, sugar, starches, and milk powder.

Diverse speeds

* Moderate: up to 10 bags per minute (600 per hour)

* Low: up to 5 bags per minute (300 per hour)

Advantage

The automatic packing machine can realize automatic operation without manual operation. •Adopt advanced sensing technology and weighing system to ensure accurate packing. It can adapt to different materials and bag sizes, with flexibility and adaptability.Monitor and adjust the packaging process in real time to ensure stable packaging quality.•Save human resources and improve work efficiency.

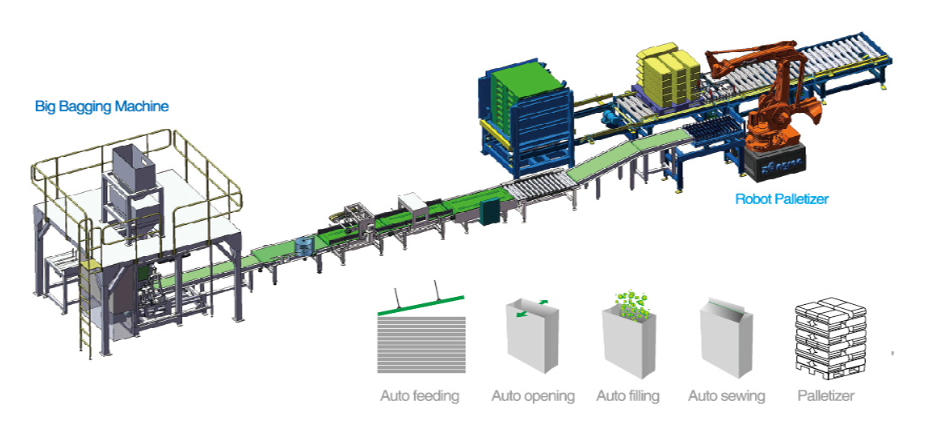

Automatic Packaging Line

The automatic packing machine can realize automatic operation without manual operation. Adopt advanced sensing technology and weighing system to ensure accurate packing. It can adapt to different materials and bag sizes, with flexibility and adaptability. Monitor and adjust the packaging process in real time to ensure stable packaging quality. Save human resources and improve work efficiency.

| Model | ZAPM-Z-50 |

| Material | SUS304 Contact parts |

| Gross Weight | 5T |

| Packing Capacity | 450-600bags/h |

| Weighing Range | 5-50kg or Customized |

| Quantify Precision | ±0.2% |

| Power | 10kw |

| Power Supply | AC 220V/380V 50 HZ 1P/3P Customized |

| Air Source | 0.4~0.6MPa 0.36m³/min |

| Application Materials | Applicable for packing granular or particle materials such as chemistry, fertilizer, grain, rice, sand, wood pellets, animal feed, urea, phosphate, PP, PE granules, construction materials, etc. |

PRODUCT DETAILS

Performant

* Quick and consistent bag handling, filling, and posing thanks to servo motors

* Multi-language with quick automatic bag size changeovers

* Fast commissioning

Precise

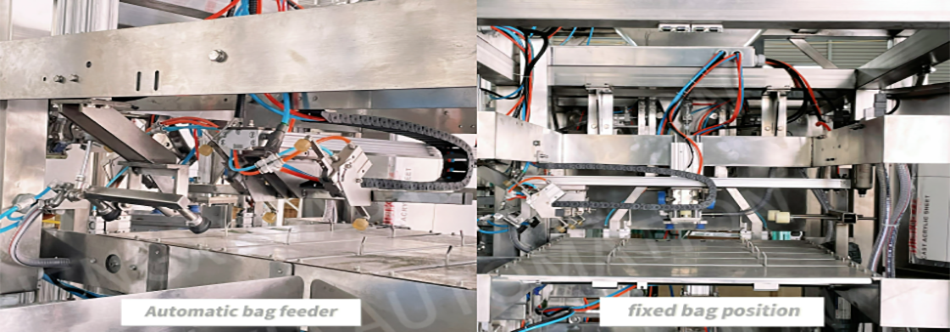

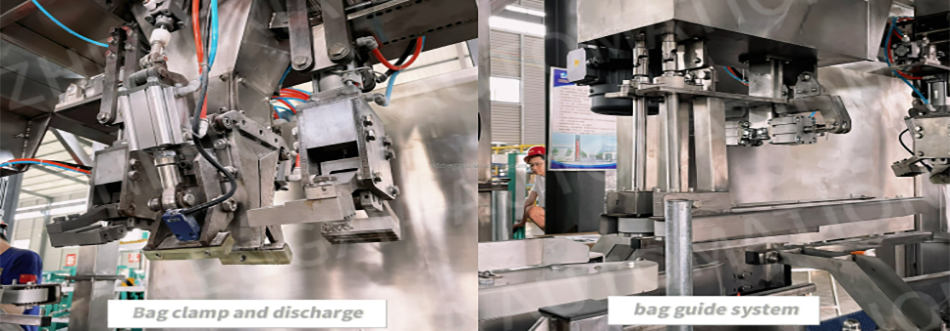

* Adjustable spout opening to accommodate various bag sizes

* Bag detection on the filling spout to prevent spillage without interrupting the bagging process

* Total control of the bags for optimal seals and finished product quality

Safe and ergonomic

* Bag magazine with multiple stacks for greater autonomy

* Parts in direct contact with the product are made of stainless steel 304

* Height adjustable closing conveyor

* Large access doors for easy cleaning and maintenance

* Separated power and control cabinets with air conditioning

COMPANY PROFILE

BENSON Intelligent Equipment (Shandong) Co., Ltd. is a modern high-tech enterprise, focusing on the research and development of industrial robots, palletizing robots, palletizers, high-position palletizers, fully automatic bagging packaging machines, packaging machines, batching equipment, depalletizers, loaders, logistics automation lines and other projects. The company has brought together a group of high-level and high-quality professionals. The company actively promotes the development model of “production, learning and research” and has successfully developed a new generation of automated production lines that can be widely used in automated packaging and automated logistics engineering. Its capabilities and various technical indicators are at a high level. In order to comprehensively improve its market competitiveness, the company has selected a large number of high-quality accessories from the United States, Japan, Europe and other countries, and introduced various advanced processing equipment to greatly improve the quality of its products. It has been widely used in chemical, feed, flour, building materials, food, beverages, beer, automated logistics and other industries. From product import to output, from electrical control to mechanical structure design, BENSON Intelligent Equipment (Shandong) Co., Ltd. can fully provide system technical solutions and precision manufacturing of equipment. At the same time, we have a complete after-sales service system to provide you with high-quality technical support and after-sales service.

Company Qualifications

Customer site

PACKAGING & DELIVERY

Customer feedback

FAQ

Q1: May I know how long it takes to get the machine after transfer?

A1: Usually, if the machine you need is a standard type, we can ship it within 7 days. Customized types are welcome, and the delivery time is about 20-25 working days. Q2: How long is the product warranty period?

A2: The product warranty period is 12 months. Q3: Can you help me pack other goods together into the container?

A3: Yes, of course. If most of the products are purchased from us, and other products are also purchased from other suppliers, you can ask other suppliers to send the products to our factory (Tai’an City, Shandong Province). We help you pack all your products into one container. Arrange everything. Q4: After the machine is finished, how to check the quality of the machine?

A4: We have made video calls with customers in seminars for on-site inspection on zoom, Microsoft, Teamviewer, whatspp, skype and wechat.

Automatic wrapping machine are achieving the leap from "mechanical operation" to "intelligent empowerment" through continuous technological innovation.

View detailsBenson is a manufacturer of column palletizing robots (manipulators) for bagged mortar, gypsum powder, bagged oils and fats, pesticide raw materials and concentrated feed. Its assembly line equipment palletizes neatly and efficiently. It also prov...

View detailsAs a manufacturer of high-speed carton packing robots, Benson's servo-driven packing robots can be widely used in high-speed packing operations of products such as bagged tea, rice noodles, disinfectants, and small bottles of perfume.

View detailsBenson's column palletizer robots are affordable and include a complete production line of carton column palletizers, pesticide and chemical industry column palletizers, bio-protein raw material packaging machine column palletizers, as well as aut...

View details