Characteristics of industrial palletizing robot

91Palletizing robot have developed rapidly in many fields with their own advantages, and they are often seen in many industries such as manufacturing.

View detailsSearch the whole station

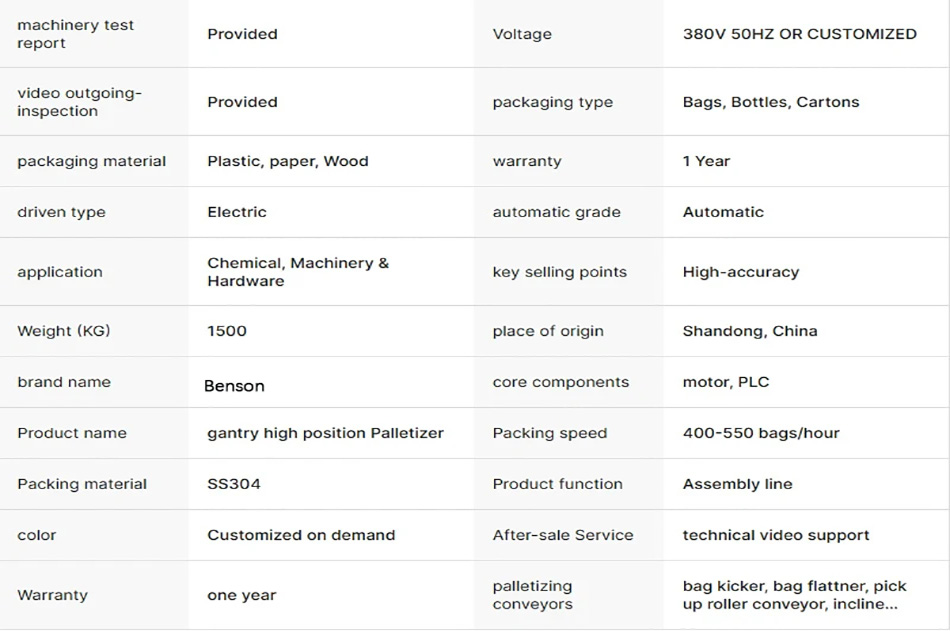

Key attributes

Product descriptions from the supplier

Video Description

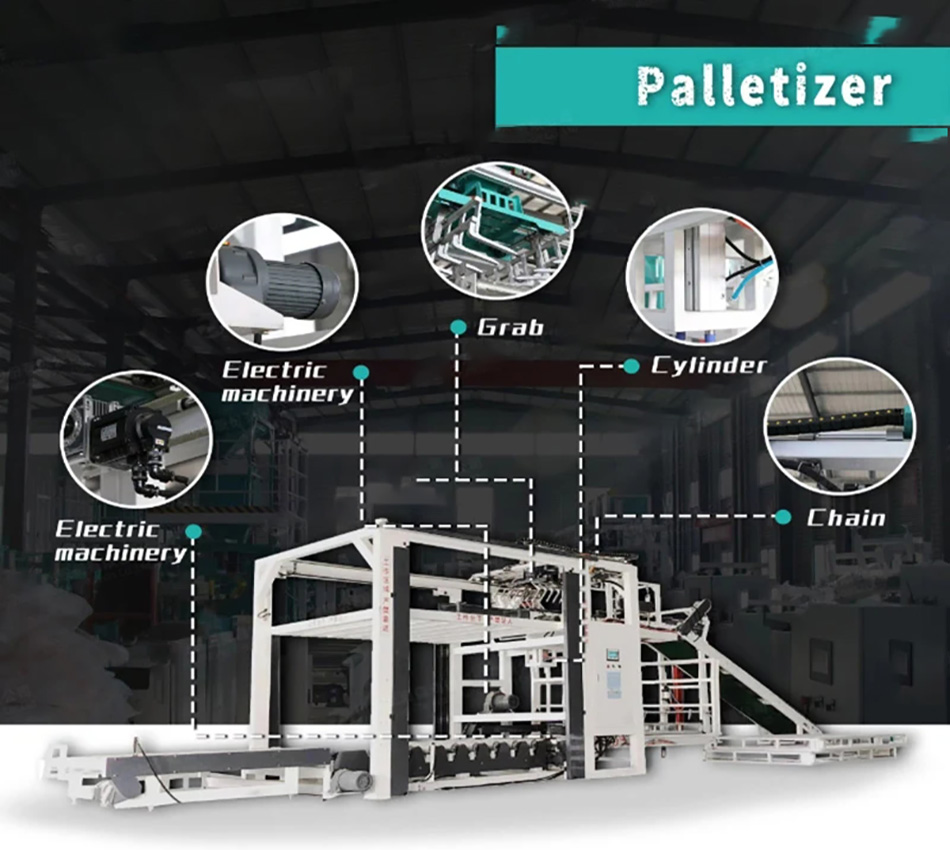

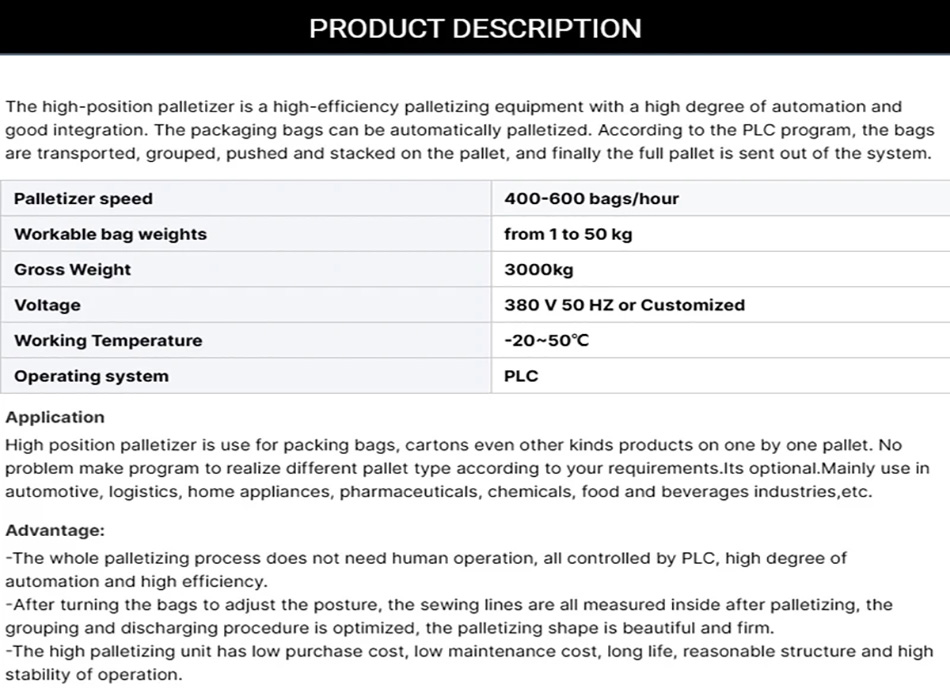

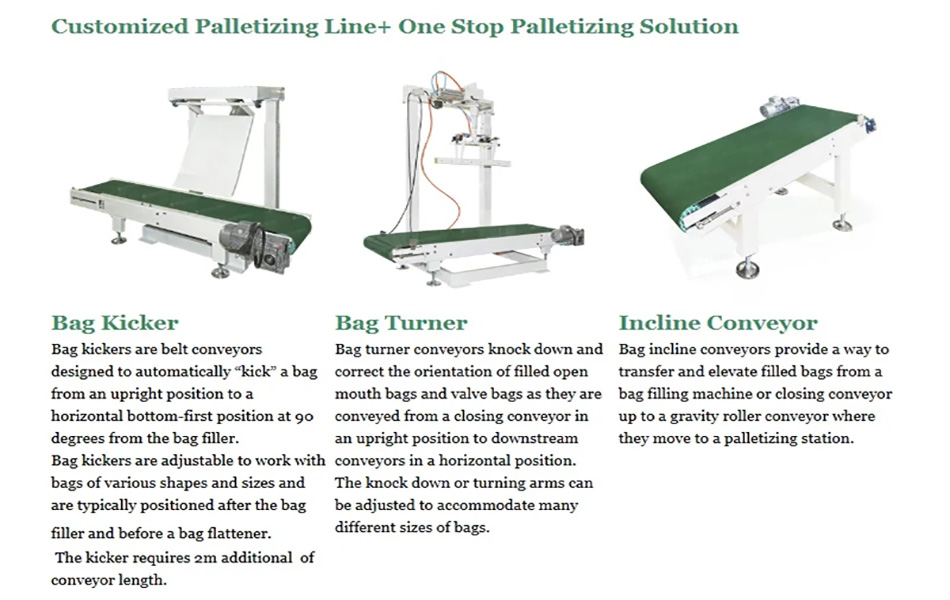

Product Description

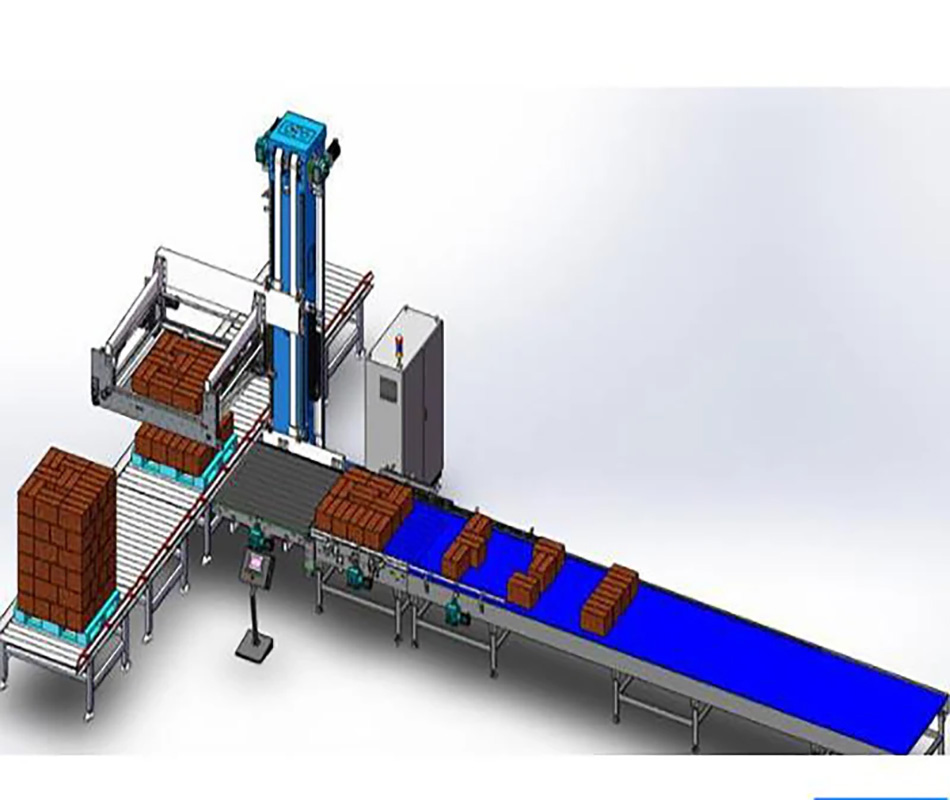

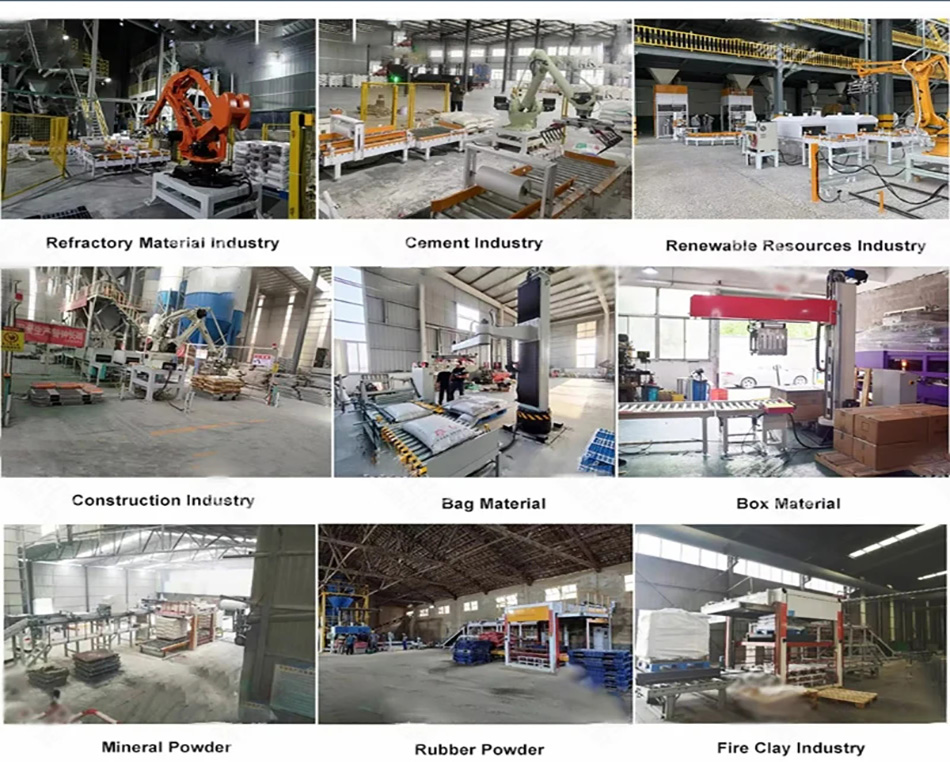

High-level palletizing robots are a type of equipment specifically designed for automated stacking of packaged items, especially for palletizing granular or bagged products such as rice, millet, grain, and beans. Here are some of the features and advantages of this type of robot: High degree of automation: These robots can automatically complete the entire process from bagging, handling to palletizing, greatly reducing manual intervention and improving production efficiency. High precision: Palletizing robots can accurately locate and grab materials through advanced sensors and control systems to ensure neat and stable palletizing and reduce errors and breakage caused by manual operation. Space saving: High-level palletizing robots can palletize in the vertical direction, effectively utilize warehouse space, and increase storage capacity. Durability and stability: These robots are usually made of high-strength materials, can withstand long-term, high-load work, have a low failure rate, and relatively low maintenance costs. Customized services: Many suppliers, such as Dongguan Haoxin Robot Co., Ltd. and Weihaosi, provide non-standard customized services, and can design and manufacture palletizing robots that meet specific working environments and product characteristics according to customer needs. Wide application areas: In addition to the food industry, such as rice, millet, grain, beans packaging and palletizing, it is also suitable for feed, chemical, grain and oil, building materials, daily chemicals, wine and other industries

Customer Sites

Company Profile

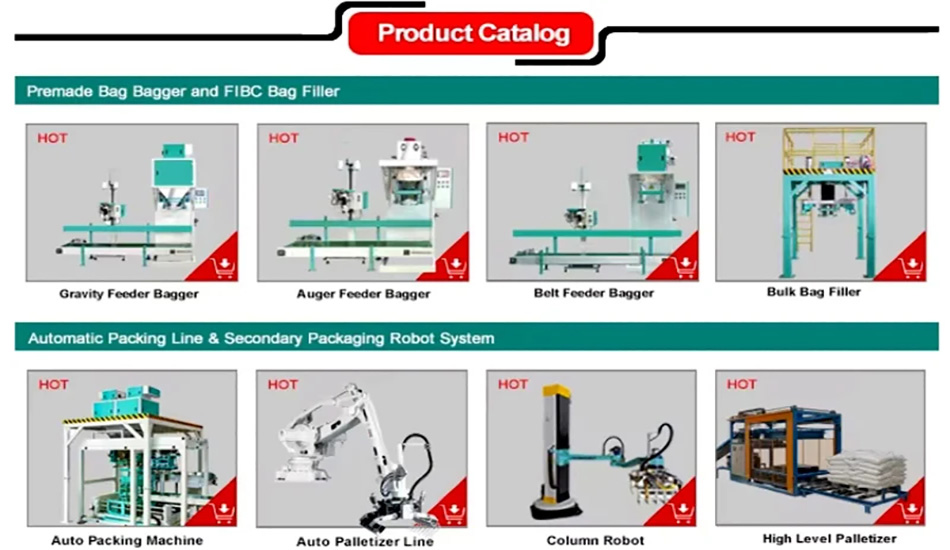

BENSON Intelligent Equipment (Shandong) Co., Ltd. is a modern high-tech enterprise, focusing on the research and development of industrial robots, palletizing robots, palletizers, high-position palletizers, fully automatic bagging packaging machines, packaging machines, batching equipment, depalletizers, loaders, logistics automation lines and other projects. The company has brought together a group of high-level and high-quality professionals. The company actively promotes the development model of “production, learning and research” and has successfully developed a new generation of automated production lines that can be widely used in automated packaging and automated logistics engineering. Its capabilities and various technical indicators are at a high level. In order to comprehensively improve its market competitiveness, the company has selected a large number of high-quality accessories from the United States, Japan, Europe and other countries, and introduced various advanced processing equipment to greatly improve the quality of its products. It has been widely used in chemical, feed, flour, building materials, food, beverages, beer, automated logistics and other industries. From product import to output, from electrical control to mechanical structure design, BENSON Intelligent Equipment (Shandong) Co., Ltd. can fully provide system technical solutions and precision manufacturing of equipment. At the same time, we have a complete after-sales service system to provide you with high-quality technical support and after-sales service.

Company Qualifications

Exhibition

PACKAGING & DELIVERY

FAQ

Q1: May I know how long it takes to get the machine after transfer?

A1: Usually, if the machine you need is a standard type, we can ship it within 7 days. Customized types are welcome, and the delivery time is about 20-25 working days. Q2: How long is the product warranty period?

A2: The product warranty period is 12 months. Q3: Can you help me pack other goods together into the container?

A3: Yes, of course. If most of the products are purchased from us, and other products are also purchased from other suppliers, you can ask other suppliers to send the products to our factory (Tai’an City, Shandong Province). We help you pack all your products into one container. Arrange everything. Q4: After the machine is finished, how to check the quality of the machine?

A4: We have made video calls with customers in seminars for on-site inspection on zoom, Microsoft, Teamviewer, whatspp, skype and wechat.

Palletizing robot have developed rapidly in many fields with their own advantages, and they are often seen in many industries such as manufacturing.

View detailsBenson manufacturers sell a variety of fully automatic packaging machines, covering the packaging needs of products such as 30 kg bags of wood chip pellets, fertilizers, and bagged rice. There are also fully automatic high-speed servo packaging ma...

View detailsAs a professional palletizer manufacturer, Benson Palletizer focuses on the research and development and manufacturing of automated equipment, providing rice palletizing robots with excellent performance,It also supports large-scale jointed wood ...

View detailsAs a high-quality supplier, Benson's high-precision high-position palletizers and high-speed palletizers save time and effort, and can be applied to the palletizing needs of large bags of materials such as 50 kg rice high-precision high-position p...

View details