The future development trend of palletizing robot

98The future of palletizing robots will present four core trends: intelligence, collaboration, greening, and scenario-based.

View detailsSearch the whole station

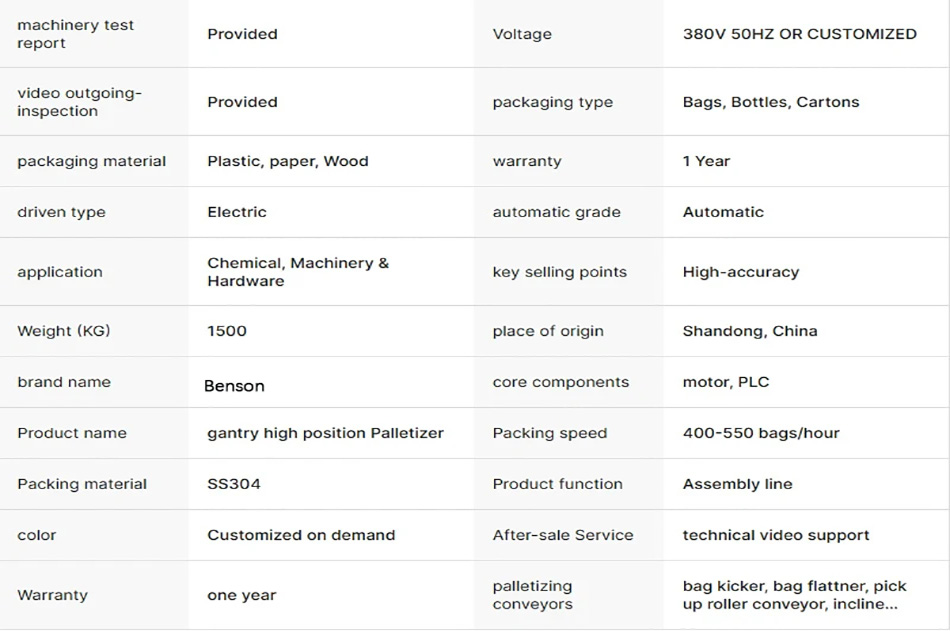

Key attributes

Product descriptions from the supplier

Video Description

Key attributes

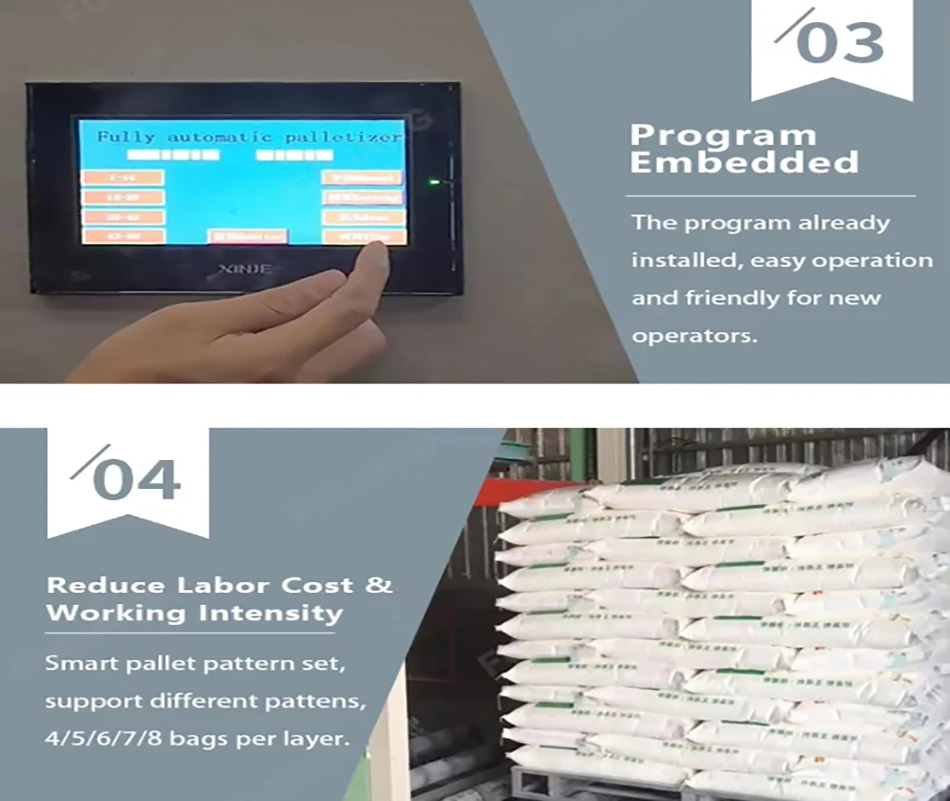

The working process of high-position palletizers usually includes core steps such as material conveying, positioning and separation, grabbing and lifting, translational palletizing, and pallet replacement. The specific process is as follows:

Material conveying and front-end preparation

Production line docking:

Material to be palletized (such as packaging bags, cartons, barreled products, etc.) are transported from the front-end equipment of the production line (such as conveyors, carton sealers) to the palletizing area of the palletizer.

Shaping and sorting:

Industrial high-position palletizer: If the materials are not arranged neatly (for example, the bagged materials may be tilted), they need to be sorted by shaping devices (such as baffles, flattening mechanisms) to ensure stability during the grabbing process.

Company Profile

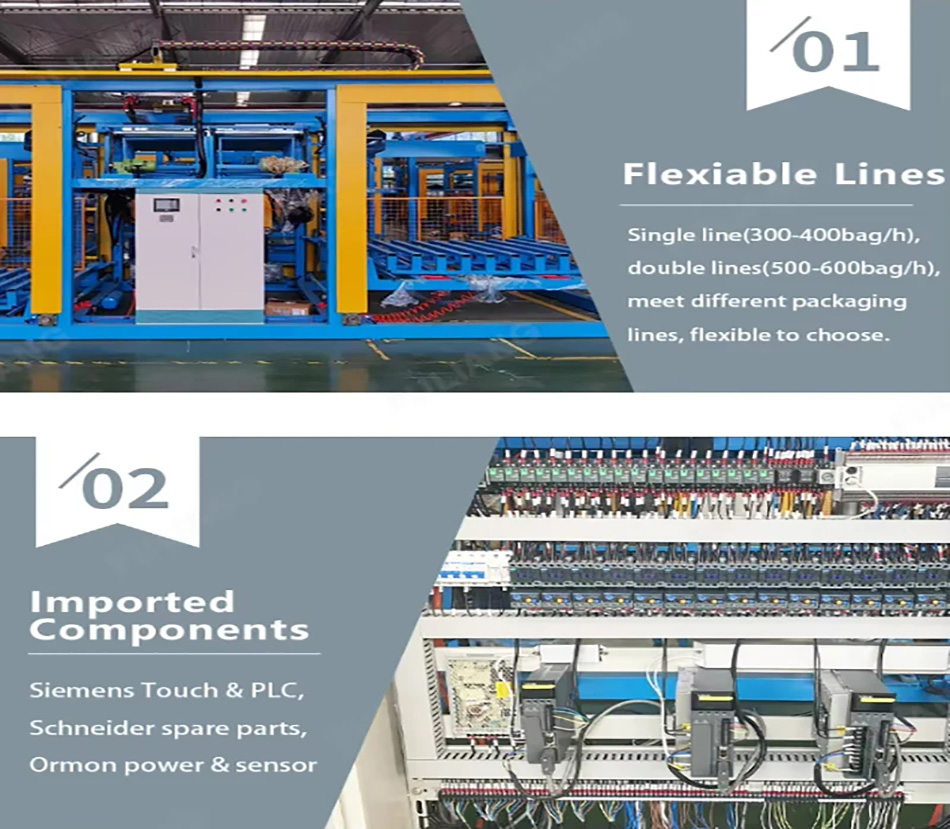

BENSON Intelligent Equipment (Shandong) Co., Ltd. is a modern high-tech enterprise, focusing on the research and development of industrial robots, palletizing robots, palletizers, high-position palletizers, fully automatic bagging packaging machines, packaging machines, batching equipment, depalletizers, loaders, logistics automation lines and other projects. The company has brought together a group of high-level and high-quality professionals. The company actively promotes the development model of “production, learning and research” and has successfully developed a new generation of automated production lines that can be widely used in automated packaging and automated logistics engineering. Its capabilities and various technical indicators are at a high level. In order to comprehensively improve its market competitiveness, the company has selected a large number of high-quality accessories from the United States, Japan, Europe and other countries, and introduced various advanced processing equipment to greatly improve the quality of its products. It has been widely used in chemical, feed, flour, building materials, food, beverages, beer, automated logistics and other industries. From product import to output, from electrical control to mechanical structure design, BENSON Intelligent Equipment (Shandong) Co., Ltd. can fully provide system technical solutions and precision manufacturing of equipment. At the same time, we have a complete after-sales service system to provide you with high-quality technical support and after-sales service.

Company Qualifications

Exhibition

PACKAGING & DELIVERY

FAQ

Q1: May I know how long it takes to get the machine after transfer?

A1: Usually, if the machine you need is a standard type, we can ship it within 7 days. Customized types are welcome, and the delivery time is about 20-25 working days. Q2: How long is the product warranty period?

A2: The product warranty period is 12 months. Q3: Can you help me pack other goods together into the container?

A3: Yes, of course. If most of the products are purchased from us, and other products are also purchased from other suppliers, you can ask other suppliers to send the products to our factory (Tai’an City, Shandong Province). We help you pack all your products into one container. Arrange everything. Q4: After the machine is finished, how to check the quality of the machine?

A4: We have made video calls with customers in seminars for on-site inspection on zoom, Microsoft, Teamviewer, whatspp, skype and wechat.

The future of palletizing robots will present four core trends: intelligence, collaboration, greening, and scenario-based.

View detailsBenson's rotary handling loading and palletizing crane demonstrates powerful automated processing capabilities, and its series of bagging automatic palletizing and loading robots covers a wide range, including robots that can efficiently complete ...

View detailsBenson's high-speed packing robot source factory focuses on unmanned packaging and packing robots, and can provide dedicated high-speed packing robots for barreled peanut oil, disinfectant, liquor, purified water and other products.

View detailsSemi-automatic packaging machines manually place the materials at the packaging position, then start the machine, and the machine automatically completes the packaging process such as metering, filling, and sealing.

View details